2025.08.31

Contents

| 1. | [News] Azbil Vietnam’s Webinar Recap: Application of Azbil Products in Food & Beverage Plants |

Azbil Vietnam recently hosted a comprehensive webinar in August 2025 focused on the application of Azbil’s advanced automation solutions in the food and beverage industry. The session, led by Thu and Sales Engineer Tùng, brought together industry professionals to explore how Azbil’s technologies can help optimize production, enhance product quality, and ensure compliance with stringent food safety standards.

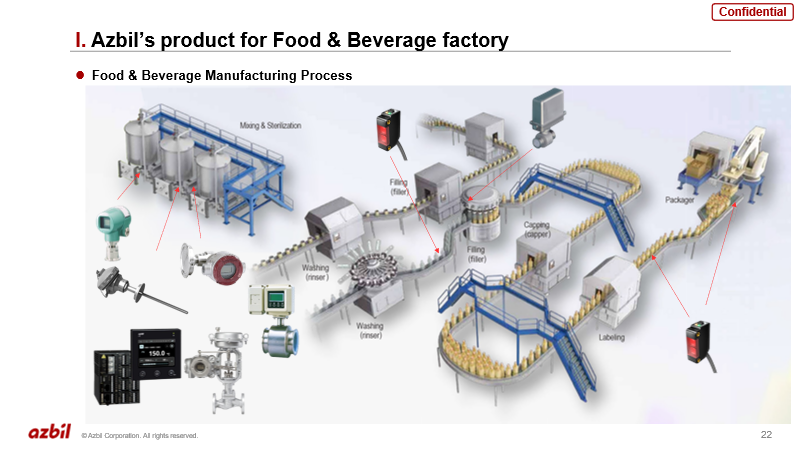

The webinar began with an overview of Azbil’s product range tailored for food and beverage plants. Tùng introduced a suite of sensors—including level, temperature, pressure, and flow sensors—alongside robust controllers and control valves. All products are engineered for hygienic applications, featuring stainless steel construction and smooth surface finishes to prevent contamination and facilitate easy cleaning. Azbil’s commitment to food safety is underscored by compliance with international standards such as ISO 22000 and FDA requirements.

Participants learned about the unique challenges faced in food and beverage manufacturing, such as accurate measurement in sticky or foamy fluids, sensor durability under rigorous cleaning processes (CIP/SIP), and the need for precise measurement in confined spaces. Azbil’s solutions include specialized sensor designs—like flat diaphragms and anti-adhesion surfaces—and multi-parameter controllers that ensure reliable operation even in the most demanding environments.

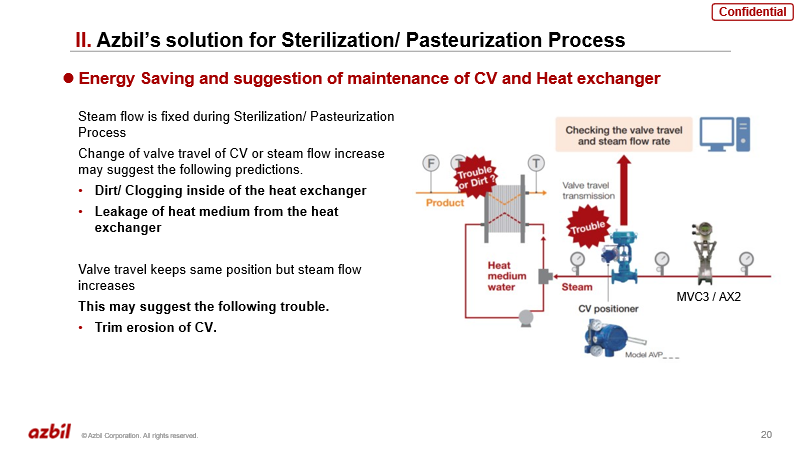

A highlight of the webinar was the deep dive into sterilization processes using plate heat exchangers. Tùng explained how Azbil’s pressure differential monitoring helps prevent product contamination, while advanced flow measurement and data recording enable both energy optimization and predictive maintenance. The use of data recorders to track sterilization effectiveness (F-value) ensures that products are both safe and of high quality.

The Q&A session addressed practical concerns from participants, including system integration, calibration, and maintenance services. Azbil Vietnam confirmed its capability to provide comprehensive engineering support, calibration, and maintenance for all devices. Technical issues such as sensor fouling in powder applications were discussed, with recommendations for easy-to-clean sensor designs and consideration of non-contact measurement alternatives. Questions on compliance and surface finishing for pharmaceutical applications were also answered, confirming Azbil’s product suitability and certification. The team clarified which valve types are appropriate for direct product contact versus utility lines in pharmaceutical settings.

The session concluded with an open invitation for further questions and follow-up support, reinforcing Azbil Vietnam’s dedication to customer success. For further inquiries, please contact the Azbil Vietnam team directly.

We would like to receive your feedback to improve for our next publish. Please feel free to contact us at:

Lưu trữ

Tất cả

©2008-2025 Azbil Vietnam Co., Ltd. All rights reserved.