Industrial Systems

We support the PDCA cycle in plant and factory operation such as in industrial automation control and monitoring systems that achieve safe and stable high-value-added production, management of such system operations, and improvements for more sophisticated operation.

Promote prompt situational awareness and swift comprehension and decision-making, and also provide guidance for correct operation: that is the concept behind the “human-centered interface” of Azbil’s DCS.

Combinations of windows required for operation or monitoring can be registered and called up as sets. This eliminates differences between operators’ views caused by differences in the screens that are displayed.

Windows are laid out in divided panes. Since information cannot be missed due to overlapping windows, this feature contributes to safe operation.

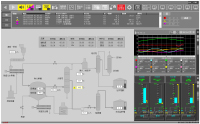

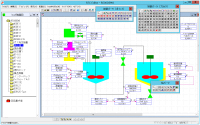

The function design tool RTC(*1) makes design, maintenance, and modification of the control system easy. This tool provides extensive online help, graphics-based process control design, operation checks using smart simulation, and remote engineering

(*1Real Time CoSEE).

Three CPUs (2-out-of-3 logic)

Three constantly synchronized CPUs perform calculations which are compared before outputting the results, helping in improved reliability.

Seamless backup

Unlike standby redundancy systems, there is no delay or wait time when switching from primary to standby unit. As a result, the system provides peace of mind for processes with fast responses and processes where safety is paramount.

Online maintenance

In addition to redundancy, all modules can be hot-swapped, allowing maintenance without interrupting plant operation.

Certified ISASecure

EDSA 2010.1 Level 1 certified.

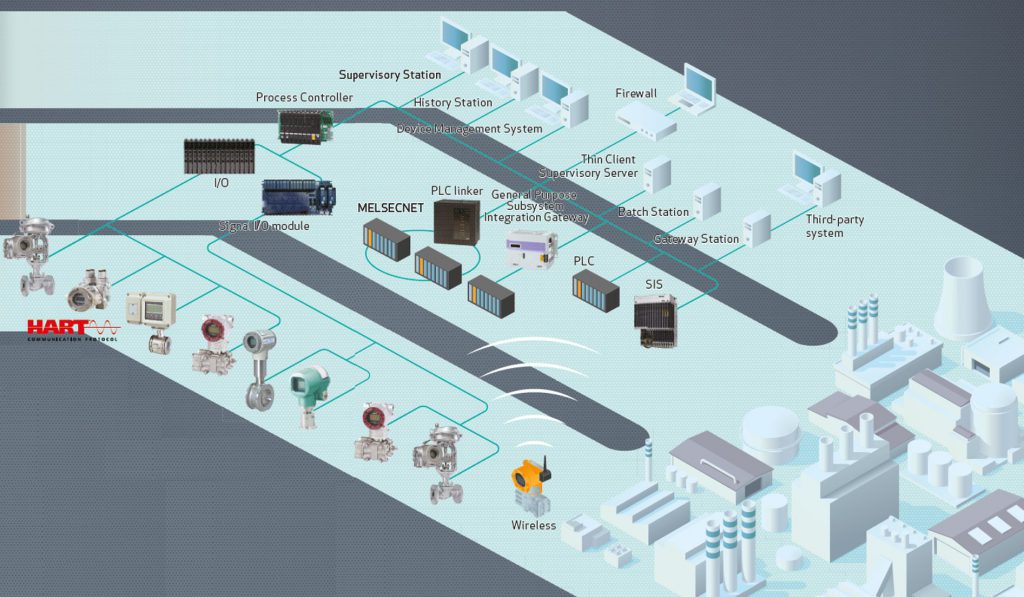

Process Controller

(*) HART is registered trademark of FieldComm Group

We could adapt to any request for control system. For years Azbil Vietnam became a trusted System Integrator for a wide range of application and markets.

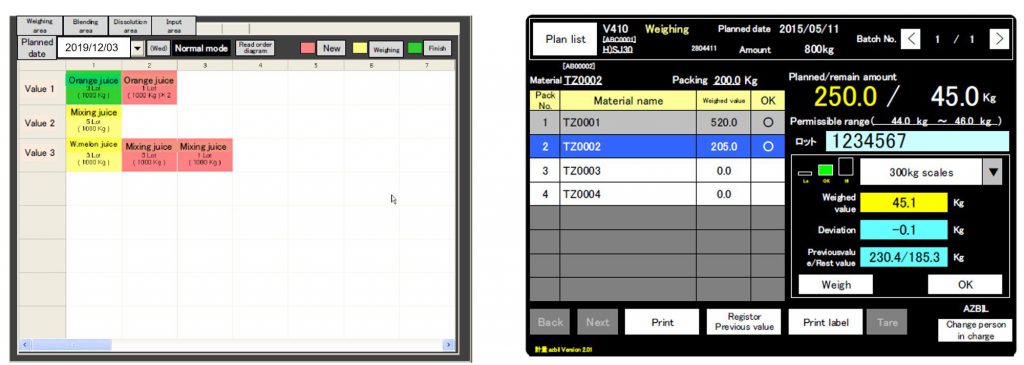

Azbil could provide solutions for highly efficient production such as:

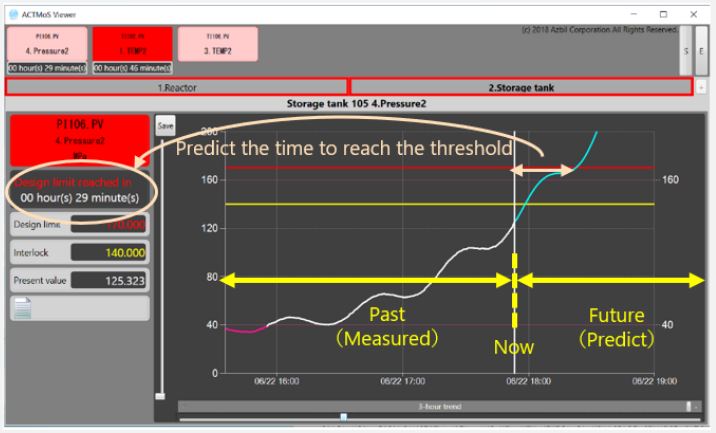

A software system that predicts the future course of critical process variables and constantly monitors them to make sure they have not deviated from control values.

The Early Warning System for time series data provides easy automatic monitoring of critical process variables, predicts future fluctuations, and visualizes predicted future fluctuations in a trend graph.

If the system predicts that future fluctuation will reach a critical control value (a value at which a protective device is activated, a value set as a design limit, etc.), it issues a predictive alarm to make the operator aware of the situation.

The Early Warning System also helps operators to respond appropriately well in advance by displaying predicted future trends and time of occurrence.

©2008-2025 Azbil Vietnam Co., Ltd. All rights reserved.