2022.08.12

| 1. | [Events] Azbil Vietnam carried out on site training and demonstration at Hoa Phat Dung Quat Steel |

| 2. | [Technical Information] Multivariable function for Vortex flow meter |

In July, Azbil Vietnam has visited Hoa Phat Dung Quat (Dung Quat IZ, Binh Son, Quang Ngai). Hoa Phat is the largest Steel Plant in the area and has a huge facilities to implement operation and maintenance. Azbil, with its strong background in steel industry, presented products, solutions and services for Hoa Phat. Azbil works contained 2 sessions, the training for Control Valves Maintenance and the Demonstration for Azbil positioner on site.

Control Valves Maintenance Training

Azbil shared our knowhow and experience in Control Valves maintenance in order for Hoa Phat Operators to understand and to carry out the basic valves adjustment. The most important thing is that Hoa Phat can plan for Control Valves maintenance with necessary steps.

On site training is a frequent activity by Azbil Vietnam to share all knowhow for our products and services. If you have any question or request please feel free to contact us via this email marketing@vn.azbil.com

Azbil Positioner Demonstration

Azbil smart positioners have many advantages:

| • | Easy to use |

| • | Durable |

| • | Cost saving |

We conducted the demonstration on customer’s valves so that they can check and confirm Azbil’s positioners’ features.

The installation for new positioner took only a few minutes which impressed Hoa Phat. One positioner could spare for all kind of valves which helps customer in optimizing their maintenance plan.

The positioner ran smoothly after installation and Hoa Phat is quite satisfied for its performance and easy-to-use feature.

More information on Azbil Smart Positioner here.

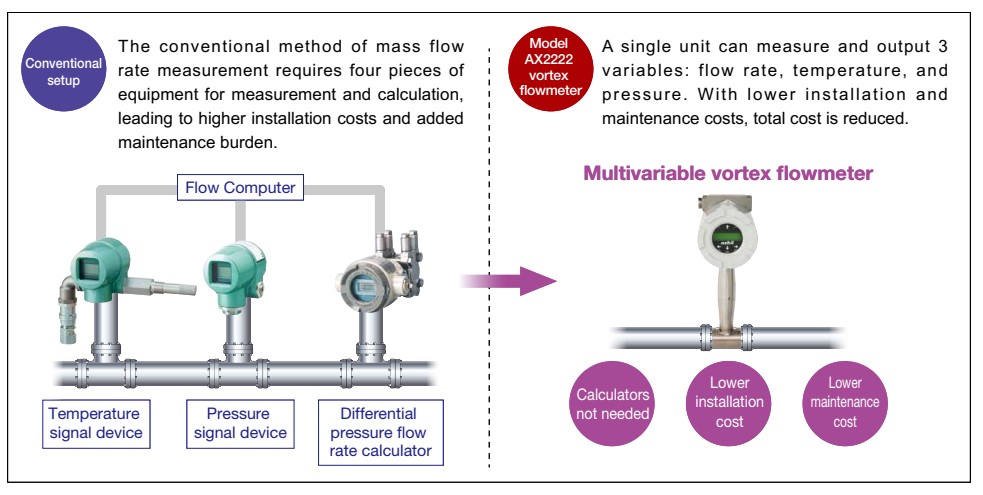

Three build-in Three built-in sensors measure the fluid’s flow rate, temperature and pressure, allowing mass flow rate measurement of various fluids (gases, liquid and steam) with density compensation.

Built-in temperature and pressure sensors make it possible to measure the temperature and pressure of fluids. With these measurements as the input for the density compensation function, highly accurate mass flow rate measurement is achieved. Three out of the following five variables can be selected for output: volumetric flow rate, temperature, pressure and calculated density.

Four in one !

By measuring the temperature and pressure of the fluid and compensating for its density, highly accurate mass flow rate measurements can be made for gases and superheated steam, whose densities fluctuate according to temperature and pressure. A single device can measure and output the flow rate, temperature and pressure, eliminating the need to install and wire multiple pieces of equipment to measure these three variables. As a result, total cost is lowered. here

We would like to receive your feedback to improve for our next publish. Please feel free to contact us at:

|

Archives

Select

©2008-2025 Azbil Vietnam Co., Ltd. All rights reserved.